In the pharmaceutical industry, the precise documentation of processes is crucial for quality assurance and compliance with regulatory requirements. It should be error-free and efficient at the same time. When revising the documentation templates, the focus was therefore on ergonomic design with clear user guidance and comprehensible language.

A medicine has come a long way before it is packaged ready for sale. The highest quality standards must be adhered to. This compliance is meticulously checked and documented. The allpack group ag - a leading service provider for pharmaceutical packaging in Switzerland – uses a paper-based document system for this purpose, among other things. The challenge for allpack consisted of three factors:

The main goal of the project was therefore to increase the clarity of the documents in order to facilitate handling and increase efficiency when completing the documents.

Fig. 1: Application of the documentation in practice. Photo allpack.ch.

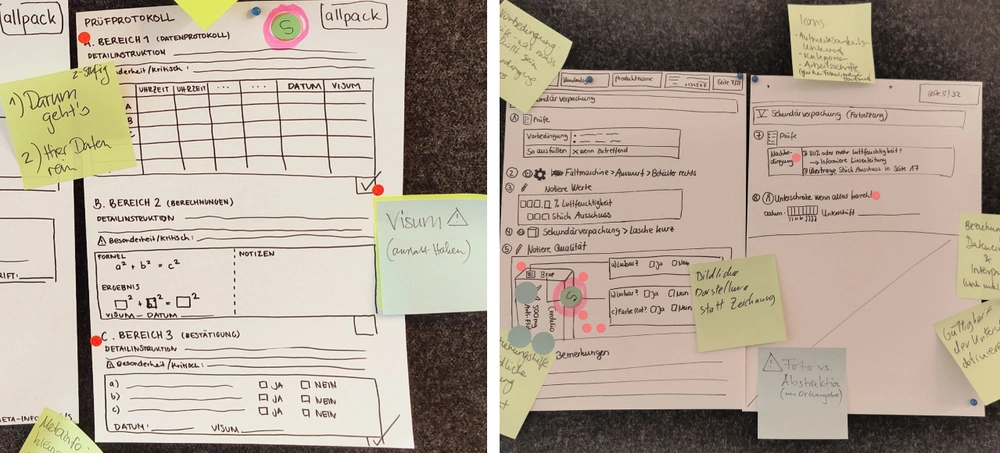

As a first step, we familiarized ourselves with the processes and existing documents at allpack group ag. This included not only a review of all existing documents, but also a detailed context analysis in production on site. In the next step, the one-day concept sprint, the strengths and weaknesses of the current documentation system and the entire internal documentation know-how were incorporated. Together, we prioritized optimization potential and developed solution ideas, which were consolidated step by step. The result was very specific draft concepts for the new documentation protocols.

A field test was carried out with the prototype of the new protocol layout in production at allpack group ag. The user test showed that the optimized concept massively reduces the workload for employees in production!

Fig. 2: Prototype variants from the concept workshop.

Further iterative optimizations in collaboration with allpack group ag ultimately resulted in the final new documentation protocol. This complies with the standards, is more intuitive to understand and is completed more efficiently.

To ensure the scalability and sustainability of our work, we created a set of rules with principles for document creation during the project. This is used by allpack employees when creating further documents.

The figures prove it: the new documentation template is a complete success.

All this, of course, without compromising on quality standards.